Structural composition

Transmission device: Provides power to the screw, enabling it to rotate and facilitating the transportation and processing of materials. It usually includes components such as a motor, a reducer, and a coupling.

Feeding device: Used to uniformly add materials into the extruder. Common examples include feeding hoppers and metering devices, which can precisely control the amount of material added.

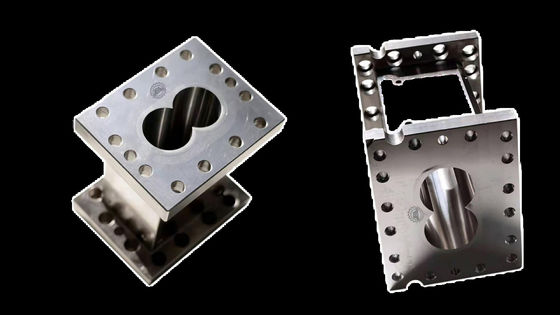

Cylinder: The component that holds the materials and the screw. It typically has an "∞" shape cross-section, providing space for the plasticization, mixing, and transportation of materials. It also features heating and cooling systems to control the processing temperature of the materials.

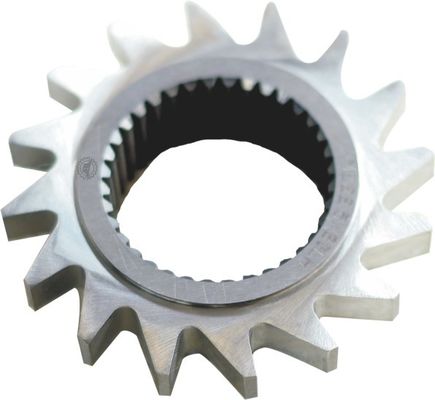

Screw: The core component of a twin-screw extruder. Two parallel screws rotate within the cylinder, using the screw's threaded structure and mutual meshing to achieve functions such as material transportation, compression, shearing, mixing, and plasticization. The screw is usually designed in a modular style and can be replaced with different threaded elements according to different processing requirements. Working principle

Concurrent-mating twin-screw extruder

Seamless-mating extruder: The low-speed extruder has a seamless-mating screw geometry, where the helix shape of one screw closely fits with that of the other screw, forming a conjugate screw geometry. It is mainly used for profile extrusion.

Self-cleaning extruder: The high-speed concurrent extruder has a seamlessly matched helix shape, which can be designed with a relatively small screw clearance to achieve a sealed self-cleaning effect. It is called a seamless self-cleaning concurrent-rotating twin-screw extruder and is used for processing special polymers.

Concurrent-mating reverse-rotation twin-screw extruder: The gap between the screw slots of the two screws in the concurrent-mating reverse-rotation twin-screw extruder is very small, allowing for positive conveying characteristics. It is often used in profile extrusion and other fields.

Non-mating twin-screw extruder: The center distance between the two screws is greater than the sum of their radii. Its conveying mechanism is quite different from that of the mating extruder, being more similar to that of a single-screw extruder, and is mainly used for mixing, exhaust, and chemical reactions, such as in the production of various engineering plastics, masterbatches, and composite materials.

Equipment classification

By screw rotation direction classification

Concurrent-rotating twin-screw extruder: The rotation directions of the two screws are the same, with good mixing, dispersion, and self-cleaning performance. It is commonly used in polymer blending, modification, granulation, and other fields, such as the production of various engineering plastics, masterbatches, and composite materials.

Reverse-rotating twin-screw extruder: The rotation directions of the two screws are opposite, with strong extrusion pressure and conveying capacity, suitable for some occasions that require high-pressure extrusion, such as profile extrusion and pipe extrusion.

By screw mating degree classification

Seamless-mating twin-screw extruder: The mating gap between the screws is very small, and the flow of the material in the screw mating area is strictly restricted, resulting in good mixing and plasticizing effects. However, it consumes a lot of power and is suitable for occasions with high requirements for the uniformity of mixing and plasticizing quality.

Non-seamless-mating twin-screw extruder: The mating gap between the screws is large, and the flow of the material in the screw mating area is relatively free. It has strong conveying capacity and relatively lower power consumption, suitable for some occasions with higher production requirements and relatively lower requirements for the uniformity of mixing. Advantages

Excellent feeding performance: For some materials with poor friction properties, single-screw extruders may have difficulties in feeding. However, double-screw extruders, especially those with meshing type, have the material transmission in a certain degree as forward displacement transmission, which can effectively solve the feeding problem.

Excellent mixing and plasticizing performance: The complex flow spectrum of materials in double-screw extruders makes them have advantages such as thorough mixing, good heat transfer, and large melting capacity. This enables the materials to be fully mixed and plasticized, improving product quality.

Good exhaust performance: It can effectively remove volatile components and gases from the materials during the extrusion process, improving the performance and quality of the products. It is suitable for producing products with lower requirements for gas content, such as high-performance engineering plastics, cable materials, etc.

High extrusion stability: It can precisely control the material delivery volume and extrusion pressure, ensuring the stability of the extrusion process, thereby improving the dimensional accuracy and stability of the products.

Good maintainability: It is easy to open, and the wear degree of components such as screw elements and inner liner of the barrel can be detected at any time, making it convenient for effective maintenance or replacement, shortening the maintenance time and reducing labor intensity.

Wide application range: It can be used for the processing of various materials, including plastics, rubber, food, medicine, chemicals, etc., and can meet the production needs of different industries. Application fields

Plastic processing: It is used for producing various plastic products, such as pipes, plates, films, special profiles, injection molded products, and raw material granulation, etc. It can also modify plastics by adding fillers, reinforcing fibers, toughening agents, flame retardants, etc. to improve the performance of plastics.

Food processing: It can be used to produce foods such as noodles, biscuits, candies, breakfast cereals, snack foods, nutritional rice flour, artificial meat, etc., and can realize the processing steps of material mixing, maturation, and shaping.

Chemical field: It is used to produce chemical products such as paints, adhesives, pigments, inks, rubber products, etc. It can perform operations such as mixing, dispersion, and reaction on raw materials.

Pharmaceutical field: It can be used to produce pharmaceutical products such as tablets, capsules, granules, etc., and can realize processing steps such as mixing of drug raw materials, granulation, and coating to improve the quality and stability of drugs.

Selection points

Production capacity: Choose the appropriate specification of twin-screw extruders based on the required output. Generally, it is measured by the extrusion output per hour (kg/h).

Screw diameter and aspect ratio: The larger the screw diameter, the stronger the production capacity; the larger the aspect ratio, the longer the residence time of the material in the screw, and the better the mixing and plasticizing effect, but the power consumption will also increase. The appropriate screw diameter and aspect ratio should be selected according to the material characteristics and processing requirements.

Rotation speed and torque: High rotation speed can improve production efficiency. However, for some heat-sensitive materials or processing processes requiring high torque, a suitable rotation speed and torque should be selected for the extruder.

Drive power: Select the appropriate drive power based on the specifications of the extruder and production requirements to ensure the normal operation of the equipment.

Automation level: Consider whether the control system of the extruder is advanced, whether it has functions such as parameter recording, formula management, and remote control, to improve production efficiency and the stability of product quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!