Product Description:

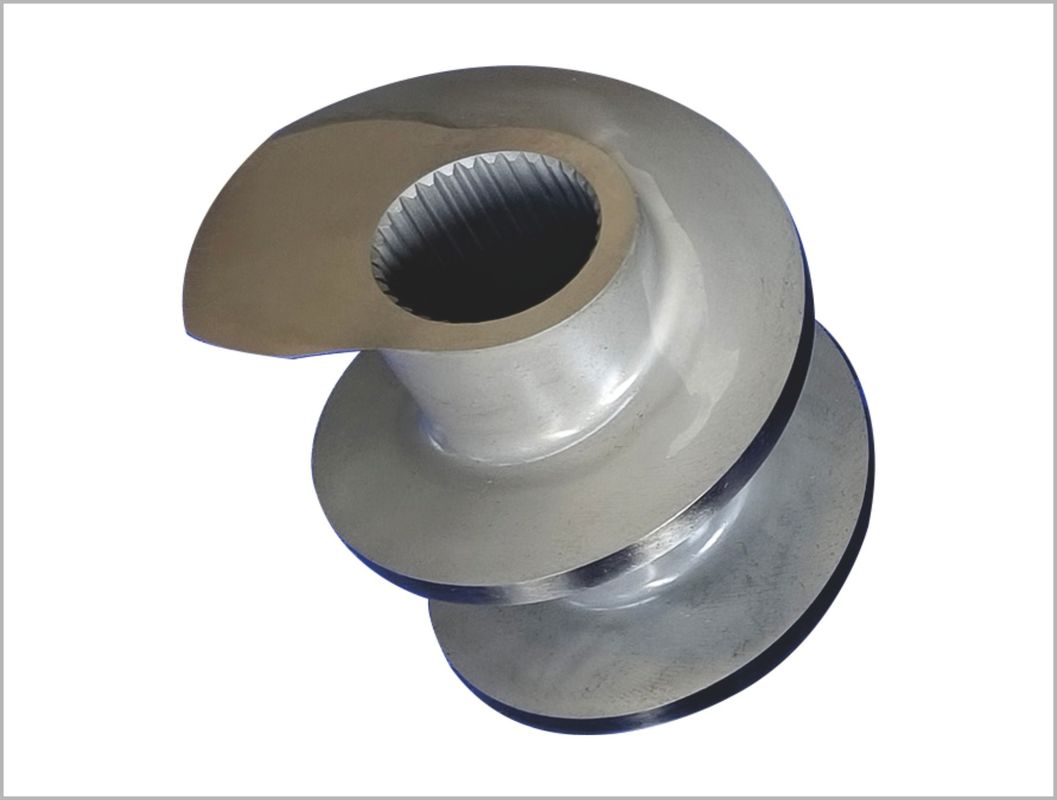

The Covey Screw Element is a high-quality, versatile component designed to meet the diverse needs of modern material handling and conveying systems. Manufactured as a brand-new product, it ensures optimal performance and longevity, making it an ideal choice for industries requiring reliable and efficient screw conveyor elements. The Covey Screw Element is engineered with precision, allowing it to seamlessly integrate into various conveyor setups, enhancing the overall efficiency of bulk material transport.

One of the key features of the Covey Screw Element is its customizable flight diameter. This flexibility allows the product to be tailored to specific operational requirements, accommodating different material types, volumes, and conveyor dimensions. Whether the application demands a smaller diameter for fine materials or a larger one for bulkier substances, the Covey Screw Element can be precisely manufactured to meet these specifications. This adaptability not only optimizes material flow but also reduces wear and tear, contributing to longer service life and reduced maintenance costs.

Installation of the Covey Screw Element is straightforward and secure, thanks to its flanged installation type. The flanged design provides a robust connection point, ensuring that the screw element remains firmly in place during operation. This feature simplifies assembly and disassembly processes, enabling quick maintenance and replacement when necessary. The flanged installation also enhances the structural integrity of the conveyor system, minimizing vibrations and operational disruptions.

Surface treatment is another crucial aspect of the Covey Screw Element, with options including sand blasting and polishing. Sand blasting prepares the surface by removing impurities and creating a clean, rough texture that improves coating adhesion and corrosion resistance. Polishing, on the other hand, provides a smooth and shiny finish, reducing friction and facilitating easier material flow along the screw conveyor. These surface treatments can be selected based on the specific environmental conditions and material characteristics, ensuring that the Covey Screw Element performs optimally in various industrial settings.

Moreover, the Covey Screw Element is designed to operate with flexible rotation directions, supporting both clockwise and counterclockwise rotation. This versatility allows the product to be used in a wide range of conveyor configurations and operational scenarios. Whether the system requires a clockwise motion to move materials forward or a counterclockwise motion for reverse conveying or specific process needs, the Covey Screw Element can accommodate these requirements without compromising performance or reliability.

In summary, the Covey Screw Element stands out as a superior solution for material conveying applications. Its new condition guarantees freshness and reliability, while the customizable flight diameter offers tailored performance for diverse operational demands. The flanged installation type ensures secure and efficient assembly, and the surface treatment options of sand blasting or polishing enhance durability and material handling efficiency. Additionally, the capability to rotate in either clockwise or counterclockwise direction adds to its adaptability across different conveyor systems.

Choosing the Covey Screw Element means investing in a product that combines precision engineering, customization, and durability. It is an essential component for industries such as agriculture, mining, food processing, and manufacturing, where efficient and reliable material transport is critical. With the Covey Screw Element, users can expect enhanced conveyor performance, reduced downtime, and extended service intervals, making it a cost-effective and dependable choice for all screw conveyor needs.

Features:

-

Product Name: Convey Screw Element

-

Condition: New

-

Operating Temperature Range: -20 to 150 °C

-

Flight Diameter: Customizable

-

Thread Type: Metric/Inch

-

Pitch: 40 mm

-

High-quality Screw Element designed for efficient material conveyance

-

Durable Convey Screw Element suitable for various industrial applications

-

Available in multiple thread types including Metric and Inch

-

Customizable flight diameter to meet specific operational requirements

Applications:

The Convey Screw Element, specifically designed with a twin screw type, is an essential component in various industrial applications where efficient material handling and precise conveyance are critical. Its unique design allows it to function seamlessly in both clockwise and counterclockwise rotation directions, offering flexibility and adaptability to different operational requirements. This makes the Convey Screw Element highly versatile, suitable for industries that demand dynamic and reversible conveying systems.

With a helix angle of 30 degrees, the Convey Screw Element ensures optimal material flow and consistent pressure distribution throughout the conveying process. This precise angle contributes to reduced wear and tear on the screw element, enhancing its longevity and performance under continuous use. The screw element’s ability to operate under a pressure range of up to 40 bar further underscores its robustness, making it ideal for high-pressure conveying scenarios where maintaining integrity and efficiency is paramount.

The silver color of the Convey Screw Element is not just aesthetic but also indicative of its material quality and surface treatment, which provides resistance against corrosion and wear. This durability makes it suitable for challenging environments such as chemical processing plants, food production lines, and heavy manufacturing industries where hygiene and longevity are critical.

The Convey Screw Element finds extensive application in scenarios such as the transportation of powders, granules, and semi-solid materials in industries like pharmaceuticals, agriculture, and plastics. Its twin screw configuration allows for simultaneous conveyance and mixing, making it perfect for complex processes that require thorough blending alongside material movement. The ability to switch rotation directions enhances operational control, allowing for precise adjustment of material flow and direction as needed.

In summary, the Convey Screw Element is a highly adaptable and durable component designed to meet the demanding needs of modern industrial conveying systems. Its twin screw type, 30-degree helix angle, and capability to operate under pressures up to 40 bar make it an invaluable asset in a wide range of application occasions and scenarios. Whether used in clockwise or counterclockwise rotation, this silver-colored screw element ensures efficient, reliable, and consistent performance throughout its service life.

Customization:

Our Convey Screw Element product offers exceptional customization services to meet your specific requirements. Designed to operate efficiently under a pressure range of up to 40 Bar, this Screw Element ensures reliable performance in demanding environments. The standard pitch of 40 mm can be tailored to suit your application, while the flight diameter is fully customizable to match your conveyor system's needs. We provide flexible payment terms including T/T, L/C, and Western Union for your convenience. All Convey Screw Elements are supplied brand new, guaranteeing the highest quality and durability for your operations. Trust our Screw Element customization services to deliver precision-engineered solutions that enhance your material handling processes.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!